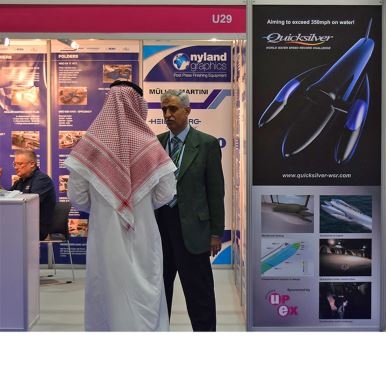

Going extra miles

Every contributor to the project can be regarded as a sponsor, howsoever they assist. But specifically on this page, we are spotlighting the firms that have between them provided almost all of the materials, equipment, manufacturing skills and specialist services and facilities that have enabled us to reach the point we are at now.

Buying the specialised equipment and facilities required to design and build a boat as sophisticated as Quicksilver would have cost many millions of pounds, and it made no economic sense for us to raise such huge investment to produce a one-off. Alternatively, paying for the use of such equipment and facilities would still have required a very substantial sum of money, and this did not appear to us to be the right option either. So instead, we ask third parties who are already geared-up with the things we need (companies, academic institutions and other organisations) to assist us, as 'sponsorship in kind'.

With the benefit of their capabilities we are able to produce a boat affordably that has top quality built-in as standard.

And this leaves us free to undertake the role and responsibility of being the design authority for the boat, and project-manage virtually everything related to it.

It should be mentioned that, in addition, we have the benefit of supporting services ranging from graphic-design and website creation to catering, logistical operations and storage. And all of this, too, has come from professionals who know their specific businesses inside out and have been willing to assist us 'in kind' in our worthy quest.

Wide-reaching collaboration has built a resilient project that's creating a world-class boat.

Advanced Communication Solutions

Big Box Photography

Competitive Carbon Composites

Eclipse Digital Solutions

Record Models

Rophea

Stoke Golding Applied Research

We also wish to acknowledge the following companies for their kind assistance in the past: Arthur Jones Motors, Fripp Design, Maple Worcester, Pyrogen, S & D Solutions, Tecserv UK, TJB Design.

Images © QWSR Ltd., except: Color-Logic image © Color-Logic Inc.; Touch7 image © Khaos Technology Inc.