Arty-Pipe

Close-up view of a detail on the jetpipe (jet engine exhaust pipe) of Quicksilver’s Rolls-Royce Spey turbofan engine, wrapped-up in protective polythene sheeting. Exhaust gases at temperatures as high as 600 degrees C course through the jetpipe, which is mounted in a tunnel that runs through the centre of the boat.

Many thanks to Unison Engine Components for making the jetpipe.

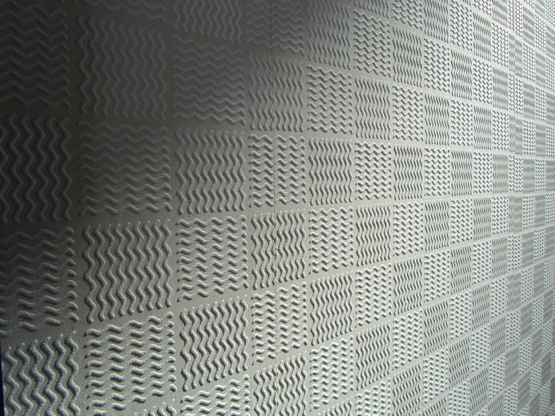

Paper View

Soft late-afternoon sunlight catches a wall in the entrance to the boat assembly area at Quicksilver’s HQ building at East Midlands Airport – home of the project for over a decade. Several thousand supporters and other guests have seen our work at close quarters on visits here, and chatted to members of the team.

Many thanks to John Kirby for decorating our HQ building.

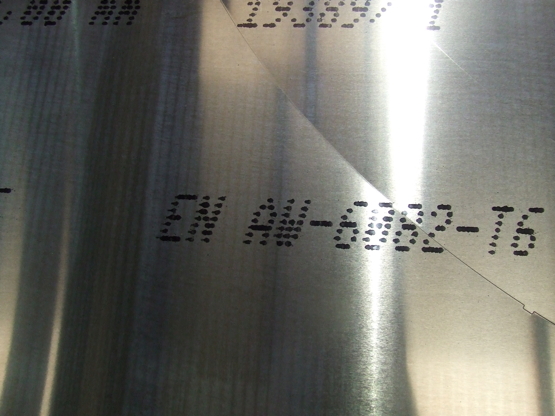

Finest Cuts

Laser-cut aluminium alloy sheet pictured in close-up during manufacture of one of Quicksilver’s internal upper-hull hoop structures. Many of the craft’s components, from large to small, are made of aluminium. As the construction process continues, so opportunities arise to view things in a different light.

Many thanks to Radshape Engineering for making the upper-hull hoop structures (and other aluminium structural components).

Show Highlights

Reflections abound as Quicksilver mirrors its surroundings at The NEC, Birmingham. The boat has been displayed as a combination of actual hardware coupled with moulding patterns and demonstration bodywork at a dozen major events in the UK.

Many thanks to UPEX and The NEC for sponsorship for the boat's three appearances at The NEC.

All images © Out of the Ordinary